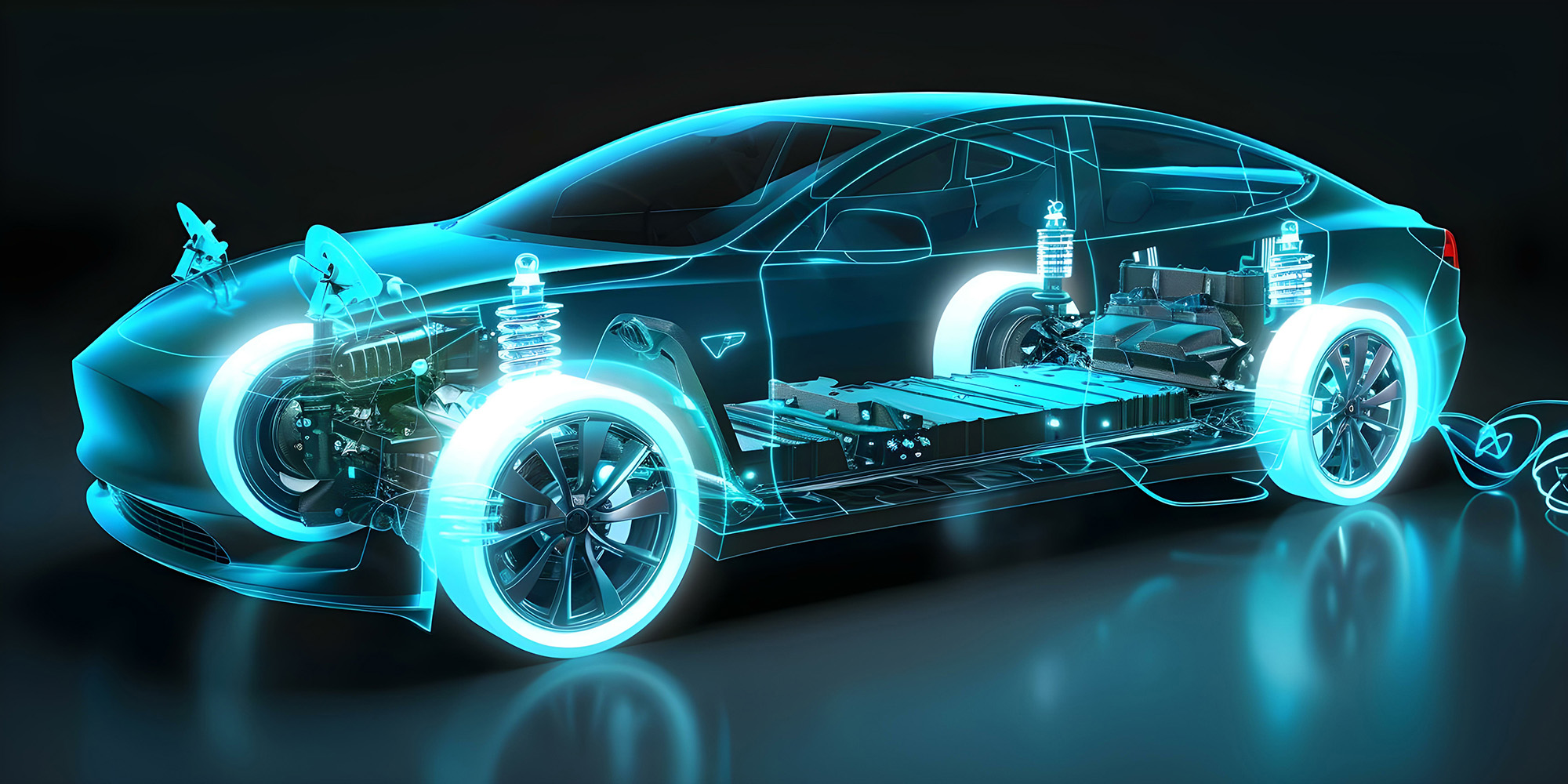

قطعات خودرو

Aug 26 , 2025کاربرد بازرسی فنی در صنعت خودرو

بازرسی فنی نظافت یک عنصر اصلی در تضمین کیفیت محصول، قابلیت اطمینان و ایمنی در صنعت خودرو است. کاربرد آن کل فرآیند را از تولید قطعات و مونتاژ خودرو گرفته تا عملکرد حیاتی سیستم و نگهداری پس از فروش در بر میگیرد. این امر در جنبههای زیر منعکس میشود:

۱. منابع و خطرات آلایندهها

۱.۱ کنترل کیفیت در تولید اجزای اصلی

اجزای اصلی خودرو (مانند بلوک موتور، پیستونها، چرخدندههای گیربکس، انژکتورهای سوخت و یاتاقانها) به استانداردهای تمیزی بسیار بالایی نیاز دارند. ناخالصیهایی مانند بقایای فلز، روغن و ذرات ساینده که روی یا درون قطعات باقی میمانند، میتوانند منجر به موارد زیر شوند:

- سایش سریع قطعات پس از مونتاژ (مثلاً وجود خرده ریز بین چرخ دنده ها که باعث ناهمراستایی می شود)؛

- گرفتگی قطعات دقیق (مثلاً گرفتگی انژکتورهای سوخت که منجر به اتمیزه شدن ضعیف سوخت و تأثیر بر عملکرد موتور میشود)؛

- خرابی آببند (مثلاً وجود ناخالصی در اجزای سیستم هیدرولیک که به سطوح آببندی آسیب میرساند و باعث نشتی میشود).

بنابراین، آزمایش تمیزی اجزا (مثلاً شستشو، وزنکشی فیلتراسیون و شمارش ذرات) در طول تولید قطعات ضروری است تا اطمینان حاصل شود که اندازه و مقدار ناخالصی با استانداردهای صنعتی (مثلاً ISO 16232 و VDA 19) مطابقت دارد تا عیوب در منبع از بین بروند.

۱.۲ تضمین قابلیت اطمینان سیستمهای کلیدی

The نظافت فنی سیستمهای کلیدی مانند سیستم سوخترسانی، سیستم روغنکاری، سیستم ترمز و سیستم فرمان خودرو مستقیماً بر ایمنی عملیاتی آنها تأثیر میگذارد:

- سیستم سوخت: ناخالصیها میتوانند فیلترهای سوخت و انژکتورها را مسدود کنند و منجر به کاهش قدرت موتور، ناپایداری در حالت درجا یا حتی خاموش شدن موتور شوند.

- سیستم روغنکاری: ذرات موجود در روغن موتور میتوانند سایش داخلی موتور را تشدید کرده و عمر مفید آن را کاهش دهند.

- سیستم ترمز: ناخالصیهای موجود در لولههای ترمز یا کالیپرها میتوانند باعث تأخیر ترمز، صدای غیرمعمول و در موارد شدید، خرابی ترمز شوند.

- سیستمهای الکترونیکی: آلودگی روغن یا گرد و غبار در حسگرها و کانکتورهای دسته سیم میتواند باعث خرابی انتقال سیگنال شود و بر عملکردهایی مانند رانندگی خودکار و ABS تأثیر بگذارد.

با نظارت بر شیوههای نظافت فنی با توجه به اجزای سیستم و واسطههای آن (سوخت، روغن، مایع ترمز)، میتوان از خرابیهای سیستمی جلوگیری کرد.

۱.۳ پیشگیری و کنترل آلودگی در طول فرآیند مونتاژ خودرو

فرآیند مونتاژ خودرو شامل مونتاژ هزاران قطعه است و بازرسی فنی نظافت مدیریت باید موارد زیر را پوشش دهد:

- محیط مونتاژ: تمیزی هوای کارگاه (مثلاً میزان گرد و غبار) و تمیزی سطح کار برای جلوگیری از ورود گرد و غبار و الیاف به بدنه یا قطعات خودرو؛

- ابزارهای مونتاژ: تراشههای روغنی یا فلزی روی ابزارهایی مانند آچار و گیره میتوانند در حین کار، قطعات را آلوده کنند.

- لجستیک: بستهبندی آسیبدیده در حین حمل و نقل و انبارداری قطعات میتواند به راحتی آلایندهها (مثلاً آب باران و گل و لای) را وارد کند.

آزمایش نظافت فنی (مثلاً بررسیهای موردی قطعات قبل از مونتاژ و پایش منظم غلظت ذرات محیطی) میتواند از آلودگی ثانویه جلوگیری کرده و عملکرد پایدار خودرو را پس از مونتاژ تضمین کند.

۲. کاربردهای جیوایبیاو کلینتک تجهیزات تست پاکیزگی در قطعات خودرو

۲.۱ جیوایبیاو کلینتک کابینتهای نظافت فنی میتواند از روشهای مختلف استخراج اجزا، از جمله شستشوی تحت فشار، اولتراسونیک، شستشوی پرفیوژن، تکان دادن و دمیدن هوا استفاده کند. روشهای استخراج مختلفی را میتوان بر اساس جزء خاص انتخاب کرد. برای قطعات کوچک، میتوان از سونوگرافی برای استخراج مؤثر ذرات آلاینده استفاده کرد؛ برای قطعات بزرگتر، شستشوی تحت فشار میتواند آلایندهها را به طور مؤثرتری از قطعات جدا کند؛ و برای قطعاتی با ساختار داخلی، شستشوی پرفیوژن میتواند بسیار مؤثر باشد.

تمیزکاری با همزن نیز نقش مهمی ایفا میکند. پیکربندی مورد نیاز برای مرحله همزن به شکل، اندازه و وزن قطعات بستگی دارد. این روش برای قطعاتی با حفرههای توکار، حداقل یک دهانه و قطعاتی که اندازه و وزن آنها همزن کافی مایع را در ناحیه آزمایش تضمین میکند، مناسب است. با این حال، این روش برای قطعاتی با ساختارهای داخلی محدود مناسب نیست.

۲.۲ سیستم آنالیز ذرات اتوماتیک (موتوری) JYBO CleanTech این دستگاه دارای عملکردهای بسیار خودکار است که امکان شناسایی و تجزیه و تحلیل دقیق آلایندههای مختلف در نمونهها را فراهم میکند. این دستگاه به طور خودکار انواع مختلف آلایندهها، از جمله ذرات فلزی، ذرات غیرفلزی و الیاف را تشخیص داده و تجزیه و تحلیل میکند و نه تنها اندازه ذرات، بلکه تعداد ذرات را نیز به طور دقیق تعیین میکند. علاوه بر این، این دستگاه دارای عملکرد تولید گزارش آزمایش تمیزی با یک کلیک است که به طور قابل توجهی کارایی و دقت آزمایش را بهبود میبخشد. با عملکرد ساده، کاربران میتوانند گزارش آزمایش تمیزی دقیقی را دریافت کنند که تضمین قوی برای کنترل کیفیت محصول ارائه میدهد.

۲.۳ صنعت خودرو استانداردهای سختگیرانهای را برای بازرسی فنی نظافت (مانند استاندارد بینالمللی ISO 16232 و VDA 19 آلمان). محصولاتی که استانداردهای بالای پاکیزگی را رعایت میکنند، نه تنها نرخ خرابی پس از فروش را کاهش میدهند (مانند کاهش ادعاهای گارانتی به دلیل ناخالصیها)، بلکه اعتبار برند و رقابتپذیری بازار را نیز افزایش میدهند. جیوایبیاو کلینتک سیستم بازرسی نظافت فنی دارای گواهینامههای استانداردهای بینالمللی و مطابق با الزامات VDA19 و ISO16232 بوده و به طور دقیق اجرا میشود.

به طور خلاصه، بازرسی و تجزیه و تحلیل فنی نظافت یک شاخص کیفیت مجزا در صنعت خودرو نیست، بلکه یک عامل کنترل اصلی در کل زنجیره صنعت است که مستقیماً با عملکرد و ایمنی خودرو و همچنین راندمان تولید و اعتبار بازار شرکت مرتبط است.