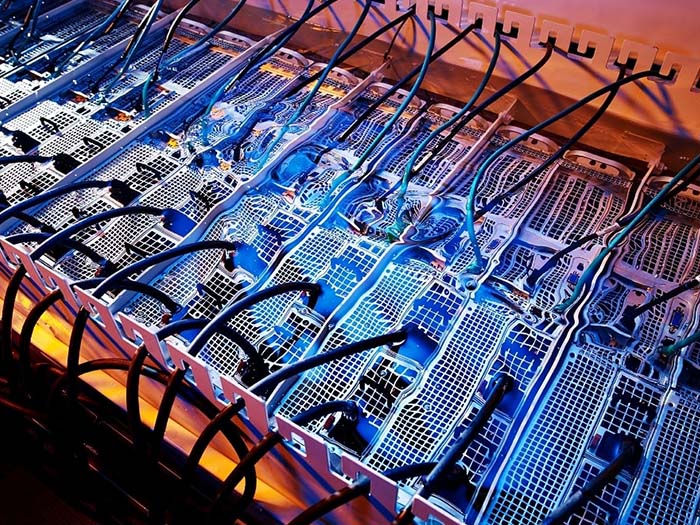

خنککننده مایع

Sep 01 , 2025کاربرد بازرسی فنی نظافت در صنعت خنککنندههای مایع

سیستم بازرسی نظافت فنی نقش حیاتی در صنعت خنککنندههای مایع ایفا میکند و بر راندمان خنکسازی، پایداری عملیاتی و طول عمر سیستمهای خنککننده مایع تأثیر میگذارد. جزئیات به شرح زیر است:

۱. منابع و خطرات آلایندهها

آلایندههای سیستم خنککننده مایع میتوانند از طیف وسیعی از منابع، از جمله بقایای تولید و نصب، ناخالصیهای مایع خنککننده، محصولات خوردگی، رشد بیولوژیکی و نفوذ خارجی، سرچشمه بگیرند. این آلایندهها میتوانند منجر به انسداد جریان، کاهش جریان، کاهش راندمان تبادل حرارت، افزایش خوردگی، فرسودگی و خرابی پمپ و از بین رفتن پایداری شیمیایی مایع خنککننده شوند و به شدت بر عملکرد و طول عمر سیستم تأثیر بگذارند.

۲. استاندارد تست پاکیزگی

برای اطمینان از عملکرد پایدار سیستمهای خنککننده مایع، آزمایش تمیزی قطعات الزامی است. آزمایش تمیزی قطعات معمولاً مطابق با استانداردهای بینالمللی VDA 19.1 و ISO 16232 انجام میشود.

۳. کاربردهای تجهیزات تست پاکیزگی JYBO CleanTech در صنعت خنککننده مایع

۳.۱ جیوایبیاو کلینتک کابینت نظافت فنی میتواند از روشهای مختلف نظافت برای شستشوی قطعات، از جمله شستشوی فشاری، شستشوی پرفیوژن، اولتراسونیک، دمش هوا و غیره استفاده کند و میتواند کابینت شستشوی نظافت فنی را مطابق با نیاز مشتری سفارشیسازی کند. به عنوان مثال، در طول فرآیند تولید صفحات خنککننده مایع، میتوان از شستشوی فشار بالا برای شستشوی کانال جریان استفاده کرد و سپس آن را خشک کرد تا محیط نصب و مشخصات عملیاتی تمیزی تضمین شود.

۳.۲ به طور کلی، قطعات در صنعت خنککنندههای مایع بیشتر با شستشوی پرفیوژن تمیز میشوند. سیستم شستشوی پرفیوژن سفارشی کابینت نظافت فنی JYBO CleanTech میتواند قطعاتی مانند لولهها و اتصالات خنککنندههای مایع را تمیز کند. محلول تمیزکننده، فضای داخلی قطعه را به طور کامل پر میکند و از جریان آشفته به جای جریان آرام برای جداسازی مؤثرتر ناخالصیها از قطعه استفاده میکند.

این دستگاه دارای یک دریچه دسترسی لوله از پیش نصب شده برای پرفیوژن و شستشوی قطعات است. دریچه برگشت پرفیوژن به جای اتصال مستقیم به دریچه آمادهسازی نمونه فیلتر، در داخل حفره دستگاه قرار دارد. این امر خلاء محفظه ناشی از اتصال مستقیم دریچههای ورودی و خروجی مایع به دریچه آمادهسازی نمونه فیلتر و همچنین مقاومت جریان ناشی از اندازه منافذ فیلتر را از بین میبرد و در نتیجه از جمعآوری ناقص ذرات جلوگیری میکند.

برای محاسبه جریان آشفته از طریق لوله، از عدد رینولدز Re>4000 که از طریق معادله Re=w*d/v تعریف میشود (w: سرعت جریان، d: قطر لوله، v: ویسکوزیته سینماتیک) استفاده میشود. جریان حجمی آشفته (dV/dt) برای سایر مایعات را میتوان با پوشش این معادله تا dV/dt=Re*d*π*v/4 محاسبه کرد.

۳.۳ سیستم آنالیز ذرات خودکار JYBO CleanTech همچنین میتواند آلایندههای موجود در اجزای استخراجشده را برای اطمینان و نظارت بر پاکیزگی تجزیه و تحلیل کند.

سیستم آنالیز ذرات خودکار JYBO CleanTech نه تنها میتواند به طور خودکار خواص ذرات، مقدار و اندازه آنها را شناسایی کند؛ بلکه میتواند گزارشهای آزمایش تمیزی را با یک کلیک تولید کند. تجهیزات مرتبط با آن مطابق با استانداردهای بینالمللی مانند VDA19 و ISO16232 هستند.